Machine Shop Services

Stinson’s Industrial has built a solid reputation for providing superior machine shop services in Memphis, Tennessee over the last twenty years. We know that your business relies on top quality machine shop services, so that’s all that we provide. We’ve based our business on two fundamental principles – quality and trust. Our clients trust us to provide them with the quality craft that they require. We deliver every time. We aim to make your life easier – we’re your one-stop shop for industrial maintenance, design, and repair services.

The machines we have in our machine shop include: lathes, vertical and horizontal mills. We also possess CNC capabilities. Stinson’s Industrial prides ourselves in being the go to company for many facilities in the Memphis area for emergencies and/or scheduled machine work.

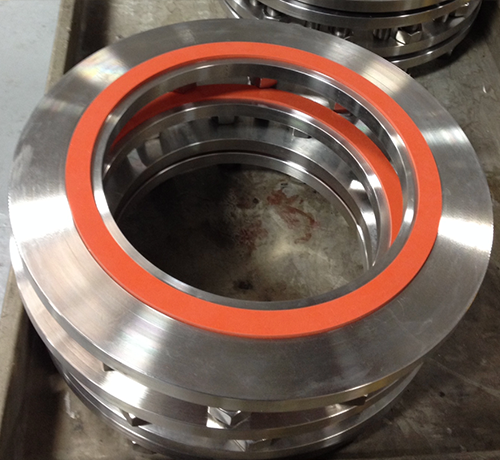

Lathe

For all your turning needs, we have a set of industrial lathes. We use the most up-to-date software to ensure precision engineering. Bring us your specs, and we’ll make sure that every component is perfectly crafted.

Vertical Milling

We can perform both vertical and horizontal milling projects. Vertical milling is a better choice for projects such as sinking dies or when you need to work with big metal plates. Projects in this line are usually worked on one side or the other. This technique is best suited to simpler jobs.

Vertical milling tends to be faster and can be more affordable than horizontal milling, depending on the project.

Horizontal Milling

Of course, vertical milling is not always the best choice. When it’s necessary to create grooves or slots in the material, or when you’re working with very heavy metal, horizontal milling is the better choice. It’s better suited to more complicated projects.

Speak to our team, and we’ll help you decide which option is better for your needs.

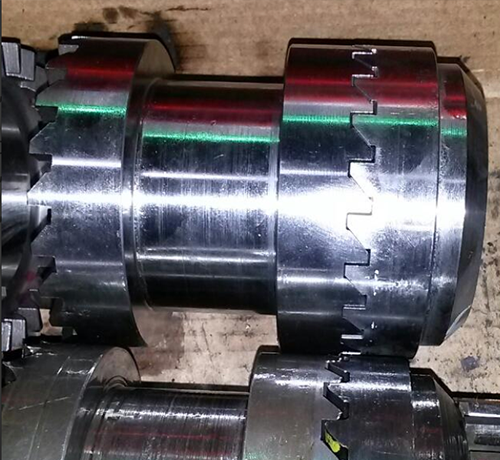

CNC

Some projects need precise engineering. There is no room for errors here – being out even a quarter of an inch can be disastrous. That’s why we use the latest computer numerical control (CNC) machining process, and the best software on the market to give you the product you want.

Using computers here makes sense – it makes it easy to get the exact results required, time and time again.

Waterjet

Being a forward-thinking company, we wanted to offer our clients the best range of options. Waterjet milling allows the precision engineering of components that might be difficult to mill using more traditional means.

The material is blasted by a highly targeted spray of water that contains abrasive particles. This results in a strong, and controlled milling process that is capable of handling a range of different projects.

This method is uniquely suited to tasks that would be considered difficult under standard milling processes. It can be used to cut a range of different materials and doesn’t involve any heat making it ideal for materials that would be easily damaged by high temperatures.

CNC

Some projects need precise engineering. There is no room for errors here – being out even a quarter of an inch can be disastrous. That’s why we use the latest computer numerical control (CNC) machining process, and the best software on the market to give you the product you want.

Using computers here makes sense – it makes it easy to get the exact results required, time and time again.

Waterjet

Being a forward-thinking company, we wanted to offer our clients the best range of options. Waterjet milling allows the precision engineering of components that might be difficult to mill using more traditional means.

The material is blasted by a highly targeted spray of water that contains abrasive particles. This results in a strong, and controlled milling process that is capable of handling a range of different projects.

This method is uniquely suited to tasks that would be considered difficult under standard milling processes. It can be used to cut a range of different materials and doesn’t involve any heat making it ideal for materials that would be easily damaged by high temperatures.

Our Machine Shop Equipment Includes:

- 10”x20” Feeler 5-C Collet

- Tool Room Lathe

- 18”x16” Industrial Lathe

- 16”x60” Industrial Lathe

- (3) Lagun Vertical Milling Machines

- Horizontal Band Saws (Can handle up to 16” wide)

- Micrometers measuring from 0”-32” With American Standard Certification

- All up to date machine tooling

Give us a call today and speak to one of our expert consultants. We’ll work with you to find the right solution for your needs. Work with us and see for yourself what many other companies have found over the years – we offer quality machine work.