Horizontal Milling

You might think that one milling machine is the same as any other. You’d be wrong. While the devices might all seem to perform a similar function, there is a range of different types and models from which to choose.

You’ll get your more generic models that are suitable for cutting a wide range of different projects fast and efficiently. Then some models can work with more precision and create more intricate designs.

Of course, the type of material used will also dictate what kind of lathe you should use. It’s simple enough to cut through a thin sheet of aluminum, for example. But you need a lot more power if you want to cut stronger metals like stainless steel and titanium.

What it boils down to is that one milling machine may be very different from another. Matching the right tool to the right project is essential if you want a flawless finish.

At Stinson’s Industrial, we offer vertical milling, horizontal milling, and CNC milling. In this section, though, we’re going to focus on horizontal milling. We also have pages on vertical and CNC milling if you’d like to learn more about those.

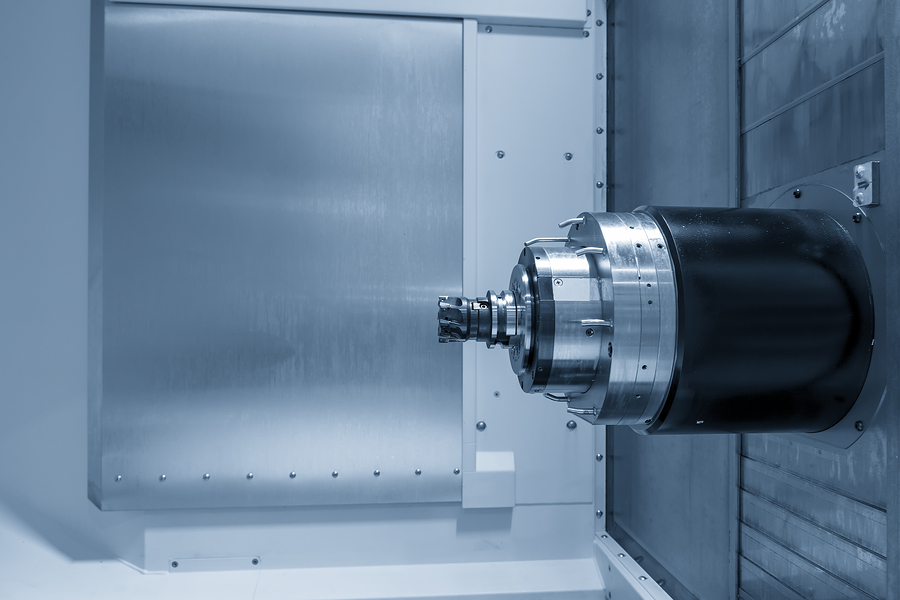

What Is Horizontal Milling?

In this instance, the machine’s cutting tool isn’t fixed in place. With horizontal milling, the cutting tool is attached to an arbor that supports it as it moves along. The arbor moves the tool along following the design specifications.

The bed will move horizontally from side to side, not up and down. Some models also allow the bed to rotate. This feature allows for the cutting of more substantial and heavier sheets of metal. With larger sheets, extra cutting heads may be installed to increase the speed of cutting.

As you fix the height of the heads, it’s not possible to alter the depth of the cuts.

The Benefits of Horizontal Milling

These types of lathes are an excellent choice for more precise, specific projects. They also work well for much larger projects, and they will do well when you require work on both sides of the sheets.

In a head-to-head match-up with a vertical model and a fundamental component, these would typically be faster. In general, though, more complex projects are going to take longer to complete. The machinery tends to be more sophisticated and more expensive to operate.

A vertical model would be more cost-effective when it comes to a more straightforward project.

Applications suited to Horizontal Milling

There are varied applications that will work well here. These include:

- Projects that require a groove or grooves to cut

- The creation of slots

- Projects that have multiple facets or require work on more than one side

- Instances where a hefty piece of metal needs to be cut

Stinson’s Industrial Lathe Services

Our horizontal milling Memphis services are the best in the state. We’re in business to make your business run more smoothly. Contact us today, and one of our friendly consultations will talk through your options with you.